TPSX Project Experience

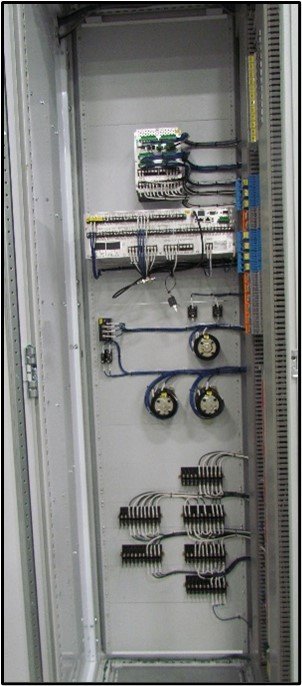

PROJECT OVERVIEW - SCADA & TRANSFORMER PROTECTION PANELS

Our Canadian company Team Power Solutions (TPS) has an extensive history of providing Industrial all types of E&I panels manufacturing service to various clients including Siemens Canada Ltd and is pleased to be the preferred panel manufacturing service provider when they require for the SCADA & Transformer Protection Panels.

Our in-house engineering and manufacturing service division were able to complete this lineup at our Manufacturing shop in Saskatoon with customer’s satisfaction.

PROJECT OVERVIEW - PARADISE ROW PROTECTION PANELS

Our Canadian company Team Power Solutions (TPS) has an extensive history of providing Industrial all types of E&I panels manufacturing service to various clients including Siemens Canada Ltd and is pleased to be the preferred panel manufacturing service provider when they require for the Paradise Row Protection Panels (x3).

Our in-house engineering and manufacturing service division were able to complete this lineup at our Manufacturing shop in Saskatoon with customer’s satisfaction.

PROJECT OVERVIEW - CLIVE BATTERY EXPANSION

The project involved providing a low-voltage motor solution consisting of 16 variable frequency drives (VFD) ranging from 25HP to 400HP at 600V. The VFD lineup solution was designed by Team Power Solutions to ensure the customer was receiving what they expected. Team Power Solutions was able to fabricate the 10 sections of the VFD lineup in only a three-week period. During this period, there were up to ten TPS employees working on the project, and this enabled Team Power Solutions to meet the customer’s schedule.

PROJECT OVERVIEW - FINNING CANADA

Our collaboration with Finning Canada is centered on the deployment of modular power systems featuring E-house configurations, occasionally utilizing split enclosures, MV switchgear, and Caterpillar diesel or natural gas generators. Engineered for adaptability, this system ensures dependable and efficient power generation across a wide spectrum of applications.

Our Canadian company Team Power Solutions will support the engineering and design phase and will be responsible for the comprehensive mechanical and electrical packaging. While Finning Canada will provide the necessary CAT equipment and major components. This collaboration highlights the capability to deliver high-quality solutions for significant energy projects, showcasing the region's talent and resources on a global scale.

TPS focuses on electrical innovation, quality, and safety, catering to heavy commercial and industrial clients across North America. Meanwhile, Finning Canada brings extensive industry expertise in mining, construction, petroleum, forestry, and power systems, aligning perfectly with their dedicated approach.

PROJECT OVERVIEW - SEABEE MINE MAIN SUBSTATION DESIGN

The project included a new 138kV substation, 25kV overhead distribution, a 25kV secondary substation, modular E-houses (including switchgear and UPS), relay protection, transformer design, load flow, short-circuit, utility liaison, ground grid design, mimic panel design, energy management system considerations, fencing design, layout, and lightning protection design. Our Team Power Solutions design group attended meetings with the representatives from Seabee, interfaced with vendors and utility, and led the tender process and evaluations of vendors.

One major challenge we faced on this project was the lack of documentation for the existing equipment. There were very few existing drawings available for any of the major electrical equipment. To mitigate this issue, we had field technicians gather information on-site, then worked closely with the on-site personnel throughout the design process. This valuable knowledge enabled the design to go smoothly and without error or erroneous assumptions.

This design was completed in April 2017, on-time and slightly under budget. Construction is scheduled to be completed in phases over the next three years. We also have a strong Electrical Services team and working with our extensive resource network, we can meet your needs from maintenance, commissioning, startup and also design.

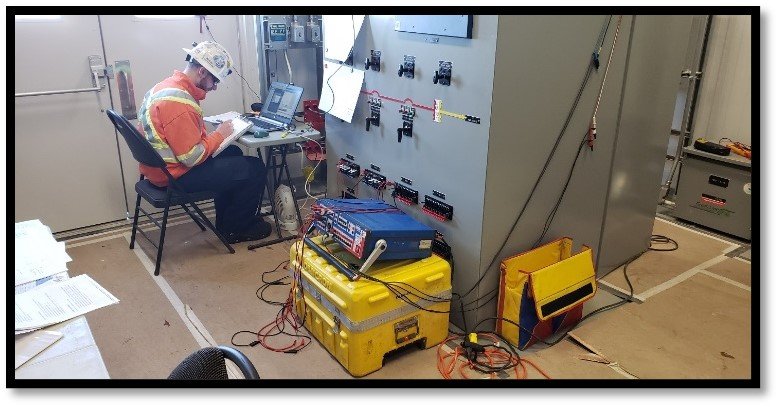

PROJECT OVERVIEW - L3R COMMISSIONING

High/Medium Voltage, Low Voltage, Mechanical Dry Commissioning, and High/Medium Voltage energization services were provided to four stations located along the Line 3 pipeline. The scope of services encompassed various tasks, including electrical and general responsibilities. In terms of electrical services, activities such as cable installation termination and testing were conducted to ensure compliance with the latest IFC version of drawings, specifications, and vendor documents. This process followed the Commissioning Guides outlined in Appendix B, as well as NETA Standards. Furthermore, support was provided to Operations during system energization and operational testing within the project scope. Assistance was also extended for the transfer of electrical process systems to operations and the energization of facilities. Additionally, the preparation and submission of turnover documentation were included in the service package. Under the general category, tasks such as device and building tagging, signage implementation, and deficiency clean-up were addressed as required.

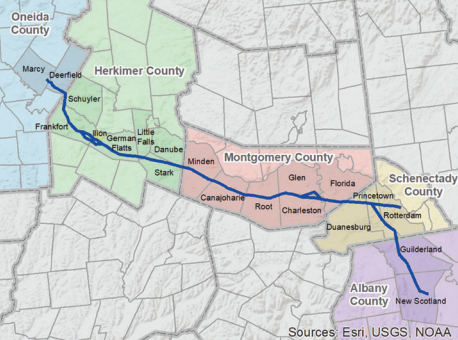

PROJECT OVERVIEW - LS POWER GRID NEW YORK PROJECT

TPSX worked on the LS Power Grid New York project in Schenectady, NY.

On this project TPSX supported the commissioning efforts and the role of Commissioning Manager.

TPSX was involved in the Gordon Road Substation Project in Schenectady, NY earlier this year. Some of the highlights of the massive equipment involved in this project included:

7 -294 MVA - Transformers

2- 637 MVA - Transformers

230kv Circuit Breakers & Disconnects

All associated protection and control.

Learn more about the LS Grid New York project at https://www.lspgridnewyork.com/